Air and ingenious nozzles could transform coatings for high temperature tolerance

Air and ingenious nozzles could transform coatings for high temperature tolerance

The air we breathe can (be used to) create high-tech, ultra-durable coatings on metal surfaces that can sustain at extreme pressure and temperature by resisting oxidation. Such coatings are useful for equipment used in power plant systems to enhance component longevity.

Engineering components in the power sector face very high pressure and temperature conditions, leading to gradual degradation due to oxidation, corrosion, and thermo-mechanical fatigue.

To protect these components, Ni-based overlay coatings widely recognized for their durability are commonly applied using thermal spray techniques like High Velocity Oxy-Fuel (HVOF), Detonation Spraying, and Atmospheric Plasma Spray (APS). These methods involve melting or partial melting of the material before it solidifies on the surface.

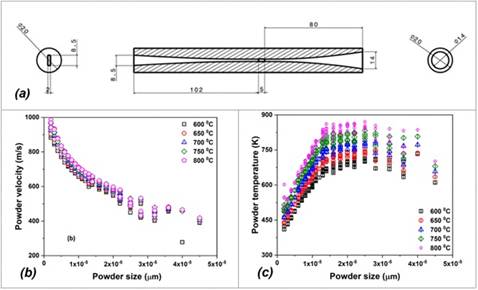

In contrast, cold spraying offers a solid-state alternative that avoids melting entirely. Using a De-Laval nozzle, it propels micron-sized particles at supersonic speeds. These particles bond to the substrate through plastic deformation, preserving the material’s original microstructure. However, commonly used cold spray processes are expensive due to the use of costly nitrogen or helium gas.

International Advanced Research Centre for Powder Metallurgy and New Materials (ARCI), an autonomous institute of Department of Science and Technology (DST) has successfully used air as the process gas, instead of the typically expensive nitrogen or helium, offering a more cost-effective and sustainable solution for the cold spray process.

Additionally, custom-designed, energy-efficient nozzles, developed and IP-owned by ARCI, an autonomous institute of Department of Science and Technology, enable effective coating at lower pressures and temperatures, reducing the process’s energy demands.

Fig: 3D Design of Nozzle and its effect on powder ((a) Nozzle geometry used to deposit the coatings; and In-flight (b) velocity and (c) temperature distribution of the powders injected in the nozzle.)

A key insight driving this innovation is ARCI’s deep understanding of how Ni–Cr alloys behave at elevated temperatures. As the temperature rises, the alloy softens, improving its ability to deform and bond upon impact. ARCI’s nozzle design increases the particles’ residence time in the thermal jet, allowing them to heat just enough to bond more effectively without needing extreme conditions. This intuitive design solution exemplifies ARCI’s strength in translating material behaviour into process-level innovation.

Using commercially available Ni–Cr powders and air as the process gas, ARCI produced dense, uniform coatings. These were thermally cycled for 1000 hours at 1100°C, demonstrating excellent performance. The formation of a dense, impermeable, columnar oxide scale confirmed the coating’s superior oxidation resistance and long-term thermal stability.

This work highlights the potential of cold-sprayed Ni–Cr coatings for high-temperature industrial applications. With its blend of material insight, process innovation, and cost-efficiency, ARCI continue to lead in delivering sustainable solutions to meet the evolving challenges of the power sector. The article was published in Surface and Coating Technology under Elsevier.