Novel method of controlling defects in MOF-Based Supercapacitors can improve energy storage

Novel method of controlling defects in MOF-Based Supercapacitors can improve energy storage

A new method of introducing controlled defects in MOF-Based supercapacitors through laser irradiation, can help enhance performance of existing energy storage technologies.

In recent years, several methods have been investigated for creating defects, such as thermal annealing, chemical exposure, high-energy ball milling, e-beam, chemical vapor deposition. However, the extent of defects could not be controlled in the materials using these methods. Traditional methods lack the precision needed for fine-tuning of defects.

In order to enhance the activity of the pristine MOF (Metal Organic Framework) without transforming it into other materials or creating a composite out of it, scientists at Institute of Nano Science and Technology (INST), Mohali, an autonomous institute of Department of Science and Technology carefully adjusted laser power to systematically regulate defects and porosity. resulting in a significant increase in the electrode’s surface area and activity.

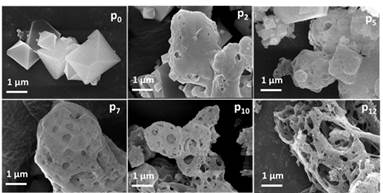

By precise tuning of the laser powers, Prof Vivek Bagchi and his team controlled the defects and porosity in pristine CuZn-BTC MOF without changing its crystal structure.

The novelty of this technique is the crystallinity of the MOF material is mostly preserved; however, the laser irradiation enhances the activity of the material.

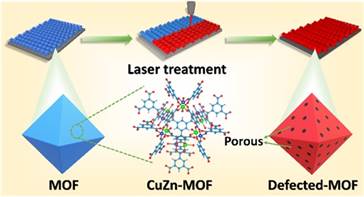

According to the researchers, upon exposure to laser radiation, some bonds in CuZn-MOF may rupture, however, the crystal structure remains intact as it is bound to a several surrounding atoms. As a result, the three-dimensional (3-D) structure of MOF may develop pores throughout, potentially capturing multiple nano-sized MOF specks. These pores provide a microchannel pathway for ion diffusion. This 3-D porous network not only increases the stability but also enhances its accessibility to ions. The MOF nano-scooplets, upon elimination, also become integrated into the system, enhancing the overall surface area.

Laser processes are quicker than traditional methods, saving time, each step of the synthesis can be precisely controlled and it is safe, clean, and environmentally friendly approach, typically requiring no chemical solvents or extra materials.

This technique published in the journal ACS Materials Letter presents an opportunity for further research, particularly if applied to various other MOFs. However, using this approach to enhance the activity of existing technologies where MOF materials are used, could lead to a significant technological advancement.

Publication link: https://doi.org/10.1021/acsmaterialslett.4c00206.

Figure1. Schematic illustration of treatment of CuZn-MOF at various laser powers

Figure 2. FESEM images of CuZn-MOF at different laser powers.

Figure 3. Graphical representation of the planar device and demonstration of the planar device’s practicality via the operation of the clock watch and LED illumination.